Industry new

Under the goal of carbon neutrality, the lifepo4 battery enterprise action "strategy"

In a world full of uncertainty, the biggest certainty in the next 30 years is that all major economies in the world will move towards the goal of carbon neutrality.

On May 10, the European Parliament’s Environmental Committee voted to pass the EU’s iconic climate change law, which means that the EU’s carbon neutrality by 2050 has become a legal commitment. The climate change law will allow the EU to embark on a green development path in the coming decades.

Prior to April 22, Chinese President Xi Jinping reiterated at the leaders’ climate summit that China will strive to achieve a carbon peak by 2030 and a strategic decision to achieve carbon neutrality by 2060, and expressed support for places and priorities where conditions permit. Industries and key enterprises are the first to reach their peaks.

The importance of elevating carbon neutrality to a legal commitment and a political strategy is self-evident: it not only means that the process of the energy revolution will be accelerated on a global scale, but it will also start a new round of industrial revolution. A wave of zero-carbon economy that has lasted 20 to 30 years and will have a profound impact on the world has kicked off.

In this zero-carbon economy wave, the lifepo4 battery industry, as the meeting point of the three major fields of energy, transportation, and industry, not only plays the role of pioneer in the carbon neutral revolution, but also will play the role of being "revolutionized." As a result, it has become the focus of attention from the perspective of carbon neutrality.

Carbon neutral power battery "AB side"

Taking China's achievement of carbon neutrality as an observation cut, carbon emissions in the power sector account for 40% of total emissions, which is the biggest battlefield for carbon reduction. The core of carbon reduction in the power sector lies in the construction of a new power system with renewable energy as the mainstay. By 2030, China's non-fossil energy will account for about 25% of primary energy consumption, and the total installed capacity of wind power and solar power will reach more than 1.2 billion kilowatts.

In this system, the energy storage system with power batteries as the main body needs to be deeply involved, coordinated with renewable energy sources such as photovoltaics and wind power, and then form a new power grid through the combination of the Internet of Things and artificial intelligence. Carbon reduction in the power sector is undoubtedly a historic opportunity for power battery companies.

However, with the rapid growth of power battery production capacity and volume, a large amount of carbon emissions will be generated in the production process of power batteries and the upstream and downstream industrial chain. As an important component of the full life cycle carbon emissions of electric vehicles, the carbon emissions of power batteries have become a core concern in the transportation field.

The data shows that the carbon emissions of battery production range from 61 to 106 kg CO2 e/kWh, which can account for more than 60% of the full life cycle of electric vehicles.

Based on this, more and more power battery companies and electric vehicle companies have begun to vigilantly realize that not only must they participate in the market opportunities brought about by carbon neutrality in advance, but at the same time, they must be forward-looking for the carbon in the entire power battery link. Emissions are systematically sorted out and traced, and action plans are quickly given.

On April 22, Envision Technology Group (hereinafter referred to as "Envision") released the company’s first carbon neutrality report and carbon neutrality timetable: it will achieve carbon neutrality in global business operations by the end of 2022, and achieve full carbon neutrality by the end of 2028. The value chain is carbon neutral. As a result, Envision has become the first Chinese company to commit to achieving carbon neutrality across the value chain.

(Long press to identify the QR code to download the report)

"When mankind is facing a systemic crisis, no country or individual in the world can take care of itself. What we can do is to act collectively as soon as possible and as early as possible." Yuanjing CEO Zhang Lei said.

Facing the pressure and challenges of carbon neutrality, Gaogong Lithium observed that power battery companies with international perspectives, including the Envision AESC under the Envision Group and Ningde Times, have begun to actively respond with practical actions.

Policy and market pressure "spread"

In fact, if you cast your vision to the world, the policy and market pressure on the power battery field under the carbon neutral target has begun to spread. This is one of the deep reasons why the Envision Group, which has an international background, has stepped up to launch the carbon neutral target.

The first to give clear policy goals is the European Union.

The EU’s recent proposal for a new battery regulation (2020/353) implements a more comprehensive supervision of the European battery industry chain, including the introduction of specific environmental protection regulations such as carbon emissions, raw material supply and demand, and the ratio of reusable raw materials.

The proposal clearly requires that starting from July 1, 2024, only rechargeable industrial and electric vehicle batteries that have established a carbon footprint statement can be put on the market.

Not only the policy side, terminal car companies have already taken action.

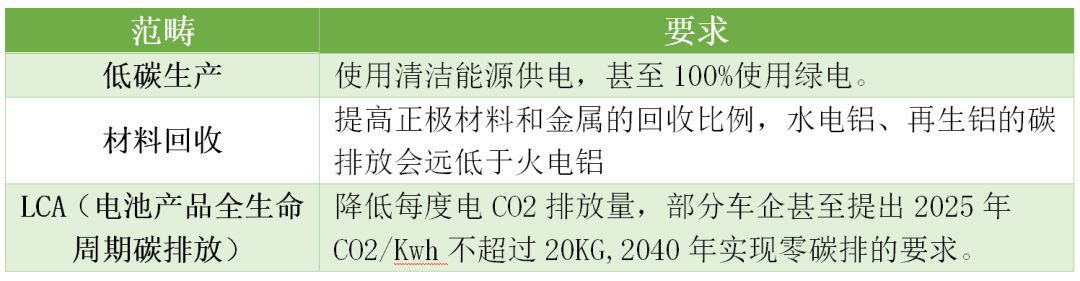

Gaogong Lithium understands that European car companies including BMW, Mercedes-Benz, Volkswagen and other European car companies have already put forward requirements for the full life cycle carbon dioxide emissions (LCA) equivalent of batteries in terms of supply chain selection. Specifically, it mainly involves three aspects:

◆ Low-carbon production-use clean energy for power supply, or even use 100% green electricity;

◆ Material recycling-increase the recycling rate of cathode materials and metals, for example, the proportion of recycled aluminum reaches 50% and the proportion of recycled plastics reaches 30%. The standards of various car companies are different, and some are more radical;

◆ Full life cycle carbon emissions (LCA) of battery products-reduce CO2 emissions per kilowatt-hour of electricity, requiring that it be reduced to 40-50kg CO2/KWh around 2024. Some car companies even propose that CO2/kWh not exceed 20Kg in 2025. In 2040, the ultra-strict requirements of zero carbon emissions will be achieved.

Faced with the spread of policy and market pressure, GGII analysis believes that for domestic power battery companies, carbon neutrality is a must-answer question that cannot be circumvented. The earlier who act, the more they can control the next initiative.

From the perspective of overseas markets, more and more Chinese power battery industry chain companies have begun to enter the supply chain system of international car companies. As the EU's regulatory threshold for carbon emissions rises, if you do not want to lose this market, you must establish a complete life as soon as possible. Periodic carbon emission data files, formulate corresponding emission reduction strategies, and achieve a reduction of more than 50% of CO2 emissions per kilowatt-hour of electricity in 2024.

From the perspective of the domestic market, under the 3060 target, carbon reduction in the domestic industrial system will soon be fully launched. As the future pillar industry of the new energy system, the power battery field will inevitably need to set an example in carbon reduction actions.

At the same time, the domestic carbon trading market is brewing, which means that the earlier you act in this field, the earlier you can enjoy the "zero carbon dividend."

Power battery carbon emissions "big data"

As a new carrier that replaces traditional fixed fossil energy (coal) and mobile fossil energy (petroleum), power batteries are the key to promoting the reform of the power and transportation fields, and the major premise to support their participation in the reforms is the production of power batteries and the whole life Whether the cycle can achieve zero carbon.

Judging from the current stage, the carbon emissions of power batteries are indeed “not to be underestimated”, which are mainly concentrated in two links, one is the production of lifepo4 battery cells, and the other is the production of key materials such as upstream positive electrodes and negative electrodes.

The carbon emissions at the cell production end mainly come from three links: the electrode section, the assembly section and the formation section. Among them, the stages of baking after coating, drying after injection, and volumetric formation are the manufacturing links that consume a lot of power. In the production of key materials for lithium batteries, the production of cathode materials consumes the most energy, followed by It is a negative electrode material.

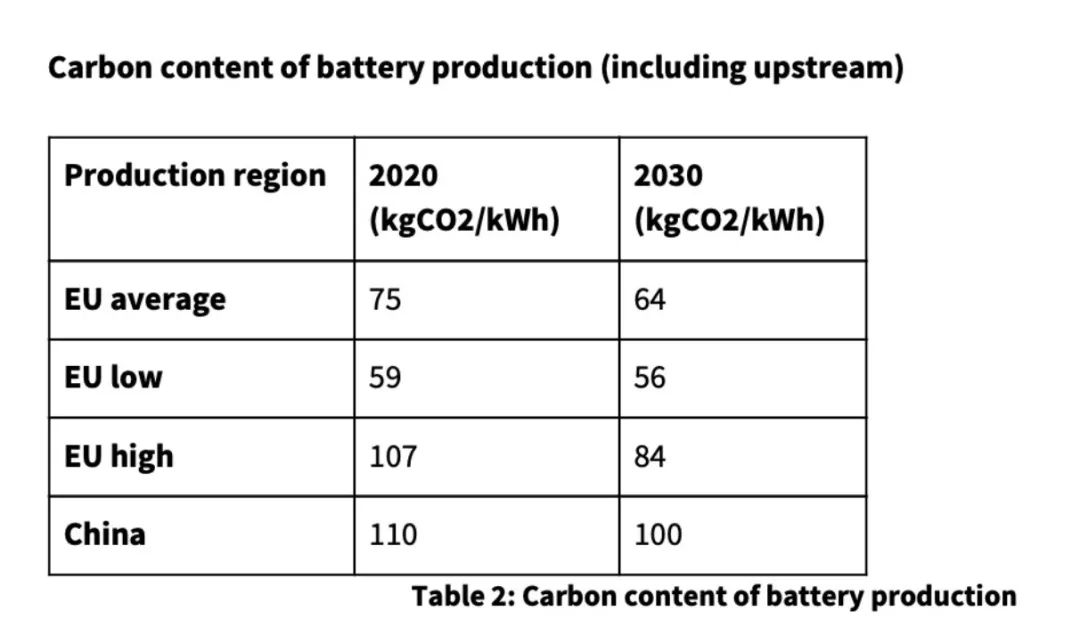

The European Transport and Environment Federation (abbreviated as: T&E) provided more specific carbon emissions estimation data in a recent research report. The study fully considers the update of the grid carbon value, the latest scientific data from the battery factory, the production location of the battery, the production period, the carbon emissions of the upstream industry, and the cathode material system. The research results show that:

The carbon emission range of power battery production is 61~106 kg CO2/kWh. The upstream part of battery production (mining, refining, etc.) is 59 kg CO2/kWh, while the carbon emissions from battery production and assembly are 2 to 47 kg CO2/kWh.

Among them, under the same battery material system, the degree of decarbonization of the grid will greatly affect the carbon emissions of battery production and assembly.

Similar to the data reported by T&E, according to research and calculations conducted by domestic professional organizations on domestic power battery companies, the carbon emission range of domestic battery production is about 100~120 kg CO2/kWh.

According to the Carbon Neutrality Report published by Envision Technology Group, Envision’s greenhouse gas emissions in 2020 are 97,255 tons of carbon dioxide equivalent (calculated based on location), of which 87% comes from the power battery business.

Among the total carbon emissions of AESC (including scopes 1, 2 and 3), electricity in scope 2 accounts for 19.4% of the total emissions, and “purchased goods and services” (supply chain links) in scope 3 account for 19.4% of total emissions. The proportion of total emissions reached 49.8%. It is predicted in the long-term that with the rapid development of business, if effective actions are not taken, emissions from business operations will increase by more than three times by 2022 compared to 2020.

Envision Technology Group's greenhouse gas emissions in 2020 (unit: tons of carbon dioxide equivalent), source: "Envision Technology Group Carbon Neutrality Report 2021"

Envision Technology Group Carbon Footprint Measurement Boundary, source: "Envision Technology Group Carbon Neutrality Report 2021"

This means that if domestic power battery companies want to significantly reduce the carbon emissions of power batteries, they must pay attention to the decarbonization of the power grid. This includes both the use of green electricity in the production of battery cells and the application of green electricity in the production of key materials upstream of the battery. .

A set of data obtained by Gaogong Lithium Battery shows that in the current domestic power system, the carbon emissions of 1kWh thermal power (North China Power Grid) are 1KG, while the carbon emissions of 1kWh hydropower are only 0.007KG, which is nearly 1/145 of that of thermal power. Using wind power, photovoltaics and other new energy power, its carbon emissions will be reduced to less than 0.005KG, which is 1/200 of thermal power.

The T&E report can clearly see the huge impact of grid decarbonization on the carbon emissions of the battery production process. In Sweden, where hydropower, wind power and other renewable electricity account for a relatively high proportion, the carbon emissions of the battery cell production process can be as low as 2 kg CO2/kWh However, in a country with a high proportion of coal-fired power such as Poland, the carbon emission of battery cell production has increased to 58-60 CO2/kWh, which is a 30-fold difference between the two.

T&E’s analysis of electric car lifecycle CO2 emissions based on power battery carbon emission data calculation under different grid decarbonization intensities in the T&E report, source: "How clean are electric cars?-T&E’s analysis of electric car lifecycle CO2 emissions"

In the domestic coal-based power system, the carbon emissions of the power battery production link are also significantly higher. The above-mentioned domestic report shows that the average carbon emissions of the battery cells of the top ten power battery companies exceed 65 CO2/kWh .

Among them, a few domestic battery companies have consciously adopted distributed wind power, photovoltaics and other forms in the factory park to increase the proportion of green power in the park, and their carbon emissions during the production of battery cells are significantly lower than the domestic average.

Corporate Action "Strategy"

Focusing on power battery production and carbon reduction in the industrial chain, head power battery companies have taken the lead.

Gaogong Lithium has noticed that power battery companies including Vision AESC, Ningde Times, and Guoxuan Hi-Tech have all taken active actions and regard this as an important part of corporate ESG or CSR.

Envision AESC: The Envision Smart Energy Industrial Park in Wuxi has established distributed wind power, distributed photovoltaic, distributed energy storage, and electric vehicle charging piles, which can meet 70% of the factory's green power demand and reduce the park's electricity cost by 15%. It is expected that by the end of 2021, the park will achieve 100% renewable energy power usage, and then achieve the goal of 100% carbon neutrality by 2022.

CATL: Carbon reduction is mainly through increasing the implementation of energy-saving projects and increasing photovoltaic power generation. In 2020, CATL will promote a total of 218 energy-saving and emission-reduction programs; in 2020, photovoltaic power generation will be 22.58 million kWh. At the same time, it has also increased its carbon footprint training for supply chain links.

Guoxuan Hi-Tech: Guoxuan's existing photovoltaic power generation and lean projects have achieved carbon emission reduction, such as the air-cooled conversion of the laser heat dissipation system of Qingdao Company to water-cooling, and the recovery and utilization of waste heat from Nantong Guoxuan's anode coating. In the future, photovoltaic solar energy will be fully installed in the production base to further reduce carbon emissions.

GGII believes that under the torrent of the era of carbon neutrality, power battery companies must have a clear understanding and high attention to their own carbon reduction, and achieve the ultimate goal through technological innovation and the synergy of upstream and downstream industrial chains.

First of all, we must clarify the company's carbon footprint, and accurately track and trace the carbon footprint of all links in the industrial chain.

Through product carbon footprint certification, companies can fully understand the high energy consumption of products, facilitate the prescription of the right medicine, and more targeted low-carbon management, energy saving and consumption reduction, and reduce production costs; at the same time, product carbon footprint certification is an environmentally friendly behavior , Is a manifestation of the company's fulfillment of social responsibility and helps to enhance the company's brand image.

At present, many power battery companies have begun to establish the monitoring and tracking of carbon emissions throughout the battery life cycle. Through accurate carbon footprint analysis, companies can not only formulate reasonable emission reduction measures based on their own conditions, but also explore more effective measures. The zero-carbon technology empowers enterprises and the industrial chain to reduce emissions.

A case for reference is that in the process of exploring its own carbon neutrality, Envision has developed and established a set of "Envision Ark" intelligent carbon management system, which can realize a full-process, end-to-end carbon solution. It can not only monitor the carbon footprint of enterprises or institutions in real time, automatically generate carbon emission reports, but also simulate and optimize the emission reduction path, and finally directly purchase green power, green certificates, and carbon sink services to achieve a closed loop of carbon neutrality in one stop.

"Vision Ark" full life cycle smart carbon management system page diagram

Secondly, based on a clear carbon footprint traceability, companies must establish short, medium and long-term carbon reduction paths for themselves and their supply chains.

In the short term, the focus of power battery companies is on the carbon neutrality of their own operations, mainly through the purchase and use of green power, optimization of production and manufacturing processes, and purchase of carbon credits.

Taking the vision as an example, its own emission reduction path mainly includes four levels. One is to continuously improve energy efficiency and increase the proportion of green power consumption through renewable energy solutions, carbon management and smart energy management systems. The second is to optimize product design to improve energy efficiency and reduce emissions.

In the medium and long term, the focus of carbon reduction in the power battery field will shift to the entire supply chain and value chain system.

Data from the Envision Carbon Neutrality Report shows that in 2020, more than 95% of greenhouse gas emissions will come from indirect emissions in the value chain outside of the group's operations.

To achieve carbon neutrality in the value chain, the upper and lower reaches of the industrial chain need to cooperate and collaborate together. Through smarter production equipment, more sustainable processes, and raw materials with lower carbon emissions, battery technology will become a real one. Zero-carbon technology.

The strategy given by Yuanjing is not only to be a pioneer in the industry, but also as an enabler of the industry. In the value chain of the industry chain, starting from external suppliers, Yuanjing will work with supplier partners to take advantage of Yuanjing’s zero-carbon The solution assists them in exploring opportunities for low-carbon transformation and helps suppliers to continuously reduce the carbon emissions of their production and operations.

In addition, in the downstream of the industrial chain, Envision is still empowering customers to help end-use carbon neutrality. Vision Intelligence has strategically cooperated with Deutsche Telekom, the largest telecom operator in Europe, to provide German electric vehicle consumers with a 100% green power smart charging solution.

At the Envision Zero Carbon Partnership Day event, Envision announced the 10 billion yuan carbon neutral fund jointly established with Sequoia Capital China, and initiated the "Key Carbon Neutral Technology" ecological partnership program, hoping to provide funds and land for more technological innovators All-round innovation support such as scenarios, together to contribute to the realization of the '3060 goal'".

Scene of the signing ceremony between Nanpeng Shen, founding and managing partner of Sequoia Capital, and Zhang Lei, CEO of Envision Group

The vision of the vision is not only to focus on its own operations and value chain emissions, but also to become a "zero-carbon technology partner" of enterprises, governments and institutions, to empower energy and industrial systems with green technology, and to help the world move towards a cleaner and smarter world. Energy system.

The zero-carbon action in the power battery industry has already begun. Whoever can take the lead in the layout and actual actions will be more likely to become the leader and winner of the global zero-carbon economy.

"One person can go fast, but a group of talents can go further." Zhang Lei said.

News

Contact Us

Companyname:Shenzhen Top New Energy Co.,Ltd.

Contact:Mr.Steven Liu

Tel:86-13602523311

E-mail:sales@topnewenergy.com

Address:Bldg 4, No. 2, Xingye Road, Songshan Lake Park, Dongguan, Guangdong.