Industry new

Nissan's lifepo4 battery supply capacity increases

With the relatively definite growth in demand for electric vehicles in the three regions of China, the United States and Europe, all car companies are revising their plans for 2022-2025.

In this regard, Japanese car companies that have previously set conservatively are also changing. According to Nikkei reports, Nissan is currently cooperating with AESC Envision Energy to invest 1.8 billion US dollars to expand factories in Japan and the United Kingdom. On the one hand, we will continue to cooperate with CATL and LG Chem, with the goal of meeting the requirement of 1 million electrified vehicles in 2023. Nissan’s 1 million includes HEV+BEV.

Part One Nissan's plan revision

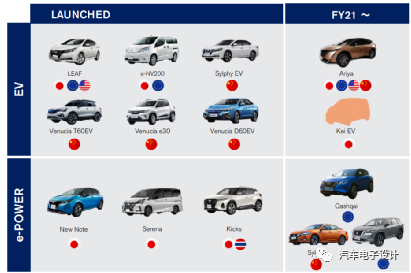

Nissan’s previous report on performance and operation on May 11 was still based on HEVs that promote extended range. As shown in the figure below, the overall BEV plan includes the Nissan Kaichen T60EV, e30 and D60EV in Japan, as well as LEAF-based Sylphy Pure Electric. After 2021, it is built around the new platform Ariya, while the domestically developed Kei EV approach is smaller.

Figure 1 Nissan's electrification process

Therefore, the Nikkei report is still very surprising. The Nikkei report is mainly about that Nissan will cooperate with AESC to invest more than 1.8 billion US dollars to build new electric vehicle battery factories in Japan and the United Kingdom. The lifepo4 battery will be produced in the two new factories as early as 2024. The goal is to The capacity increase is 700,000 BEVs to provide battery systems (200,000 for the existing, 700,000 for the new addition).

Investment in the UK started from 6GWh and expanded to 18-24GWh with funding from the British government. In addition to AESC in the UK, two AMTE Power and Britishvolt have announced plans to build a super battery factory in the UK. The goal is to build a battery production capacity of 30GWh+.

Figure 2 Battery factories in the UK

Although the design capacity of AESC can provide about 200,000 BEV products, the batteries produced in the next plant will be supplied to the Renault-Nissan-Mitsubishi alliance. The main question here is the long-term role of AESC in Nissan's supply chain.

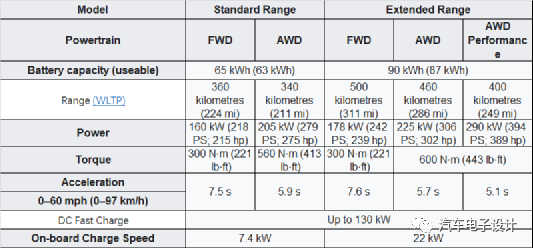

Ariya is a supplier that has introduced a new CATL. According to the current product plan, the 65 and 90kWh batteries will completely replace the existing 62kwh LEAF. The subsequent LEAF iterations are products that are biased towards the mid-city mileage of about 40kwh. Update.

So on this matter, we can make some guesses: 1) Nissan’s first batch of Ariya from 2021-2023 will still be around the existing CATL supply; 2) subsequent expansion of the platform, starting from 2024, new increments, It gave AESC the opportunity to join the expansion.

Figure 3 Ariya's product specifications

The second part of the battery supply of Nissan Renault Mitsubishi

According to the Korean media report "LG Energy Solution Expected to Set up Battery Manufacturing Plant with Renault", the French Renault Nissan Mitsubishi Automobile Alliance has decided to build two new plants in Japan and the United Kingdom this time, and is also considering openings in France, Spain, and France. Four new battery factories were built in the United States, China and other places.

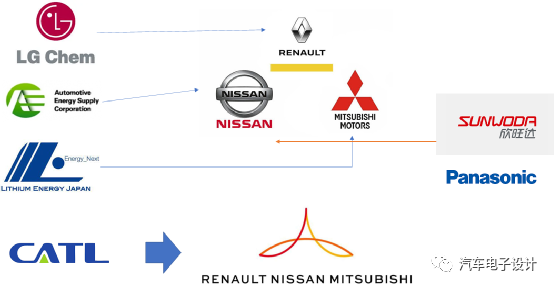

In Europe, the cooperation program between Renault of France and LG Chem of South Korea, and in China, the cooperation program between Nissan and CATL is more likely.

Remarks: In the United States, it may still build factories with LG. From this point of view, in addition to choosing CATL for a unified new platform, the original two soft package suppliers LG and AESC are also continuing to supply, and Mitsubishi PHEV batteries are also Move forward. Coupled with the supply of HEV batteries, the supply relationship of Nissan Renault Mitsubishi is shown in the figure below, and there may be new potential suppliers to join in the low-cost solution of lithium iron phosphate.

Figure 4 Complicated battery supply relationship between Nissan, Renault and Mitsubishi

summary

In the current state, there is indeed a stage where car companies are moving upwards in their planning volume. As the scale of supply goes further, car companies, no matter what they can sell, must first increase the scale of vehicle production capacity and the scale of battery demand. This and various regions encourage and promote electric vehicles to form a positive feedback, and also intensify the continuous upward rhythm of the lithium battery industry.

News

Contact Us

Companyname:Shenzhen Top New Energy Co.,Ltd.

Contact:Mr.Steven Liu

Tel:86-13602523311

E-mail:sales@topnewenergy.com

Address:Bldg 4, No. 2, Xingye Road, Songshan Lake Park, Dongguan, Guangdong.